Modern Building Services: Clear thinking on insulating plastic pipes

|

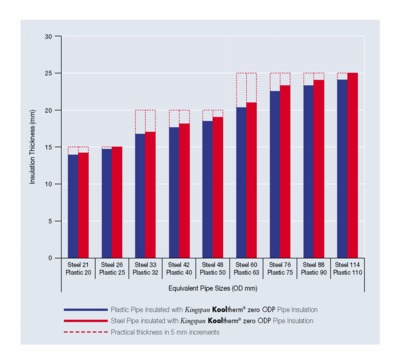

Fig. 1: Theory and practice — since the extra thermal insulation provided by plastic pipes is so small and thermal insulation comes in thickness increments of 5 mm, there is no difference in insulation requirement compared with steel pipes. |

Although plastic pipes have many benefits, requiring less thermal insulation is not one of them — as we found out from GEOFF WRIGHT.

With the growing use of plastic pipes for HVAC applications comes the feeling that less thermal insulation should be required for pipes carrying hot water. It is obvious that the thermal conductivity of plastic pipes is much less than copper and steel, so less insulation must be needed. Or is it?

Geoff Wright of Kingspan Insulation has the figures. The thermal conductivity of plastic pipes ranges from 0.16 to 0.22 W/m.K, compared with 385 W/m.K for copper and 63 W/m.K for steel. Copper has a thermal conductivity six times greater than steel, but would anyone seriously consider using less insulation on the steel pipe? The thermal conductivity of copper is around 2000 times greater than that of plastic, which is quite a different league.

However, Geoff Wright points out that the thermal conductivity of plastic is still high compared with insulation (0.021 to 0.040 W/m.K) — about six times higher. That means, he explains, that a plastic pipe with a wall thickness of 10 mm is equivalent to a millimetre or two of rigid phenolic insulation. But what about the lower surface temperature of a plastic pipe carrying hot water compared with copper or steel?

Geoff Wright’s response is that the reason a plastic pipe can be touched without undue discomfort is that the hand can carry heat away faster that it is emitted from the plastic wall of the pipe.

Likewise heat removed from the surface of a plastic pipe by radiation and convection reduces its temperature until an equilibrium is achieved.

As soon as insulation is applied, the situation changes and a steady state is achieved with the temperature at the interface between plastic pipe and insulation essentially being the same as that of the liquid in the pipe. Adding to the confusion is that the requirements in both current and proposed Building Regulations are far from clear.

When it comes to actually insulating the pipe, Geoff Wright points out that thermal insulation comes in 5 mm thickness increments, so that the slight insulation effect of the plastic pipe makes no difference to the thickness required.

Kingspan Insulation has calculated the thickness of rigid phenolic insulation required to comply with BS5422:2001 for a range of pipe sizes in both plastic and steel (Fig. 1). This chart is based on an estimated mean temperature of water in the pipe of 50°C, a thermal conductivity of 0.025 W/m.K for the insulation, 0.22 W/m.K for the plastic pipe and 50 W/m.K for the steel pipe.

No case

‘In spite of the better thermal performance of the plastic pipe, there is clearly no case for reducing the amount of insulation needed,’ says Geoff Wright. He adds, ‘Substituting other materials for rigid phenolic insulation would yield a similar graph,’

Since there is effectively no difference in the amount of insulation required on plastic and steel pipes, Geoff Wright warns, ‘Failure to install the insulation thickness specified in BS 5422 is likely to be a contravention of Approved Document L2 of the Building Regulations, which states that this standard is to be used for specifying thermal insulating materials for pipes and ductwork.’

Rather than being concerned with the very small cost savings that could be achieved even if less thermal insulation were permissible, Geoff Wright would like to see a more positive outlook. He says, ‘Quite apart from the legal requirement, there are long-term benefits to be had from the efficient insulation of pipes to reduce energy consumption. This type of whole-life-cost analysis is becoming an increasingly important part of specification. It is short sighted indeed to try to reduce costs now by skimping on long-term cost-effective elements such as insulation.

Costly

‘In the long run, this would prove costly for both the end user and the environment and, if the building doesn’t comply, costly for the contractor, since it is far easier to put insulation in place at the outset than to apply it remedially.’

Indeed, he would prefer the small extra thickness of thermal insulation on plastic pipes to be regarded as a bonus in helping to achieve the best possible energy performance for a building.

Geoff Wright is with Kingspan Insulation Ltd, Pembridge, Leominster, Herefordshire HR6 9LA.